Validation

Validation

CHC Biotech Special Validation

Our unique validation,iq, oq, pq

Validation consists of all processes under IQ, OQ and PQ and it refers to the

verification and documentation of experimental method, process, and equipment in

respect to whether it conforms to the pre-set system settings.

verification and documentation of experimental method, process, and equipment in

respect to whether it conforms to the pre-set system settings.

Q.

OUR QUESTION

Why do we need to do

VALIDATION?

All of us have endless concerns about everything.

How we can reduce the exposure risk of our researchers?

How we can create a safe and clean research environment?

How we can reduce the exposure risk of our researchers?

How we can create a safe and clean research environment?

A.

OUR ANSWER

The answer?

VALIDATION

Researchers are exposed to biohazards and many other

elements while doing experiments. To ensure their safety,

we must first have trustable equipment and facilities. For

the equipment and facility to be trustable, we must first

validate them according to the regulations and guidelines

to make sure they are safe to be used. (Validation is normally done once a year.)

elements while doing experiments. To ensure their safety,

we must first have trustable equipment and facilities. For

the equipment and facility to be trustable, we must first

validate them according to the regulations and guidelines

to make sure they are safe to be used. (Validation is normally done once a year.)

When do we need to conduct validation?

Duringinstallation

After filterexchange

After wemove the equipment

After 1 yearfrom previous validation

When the equipmentis not working as normal

-

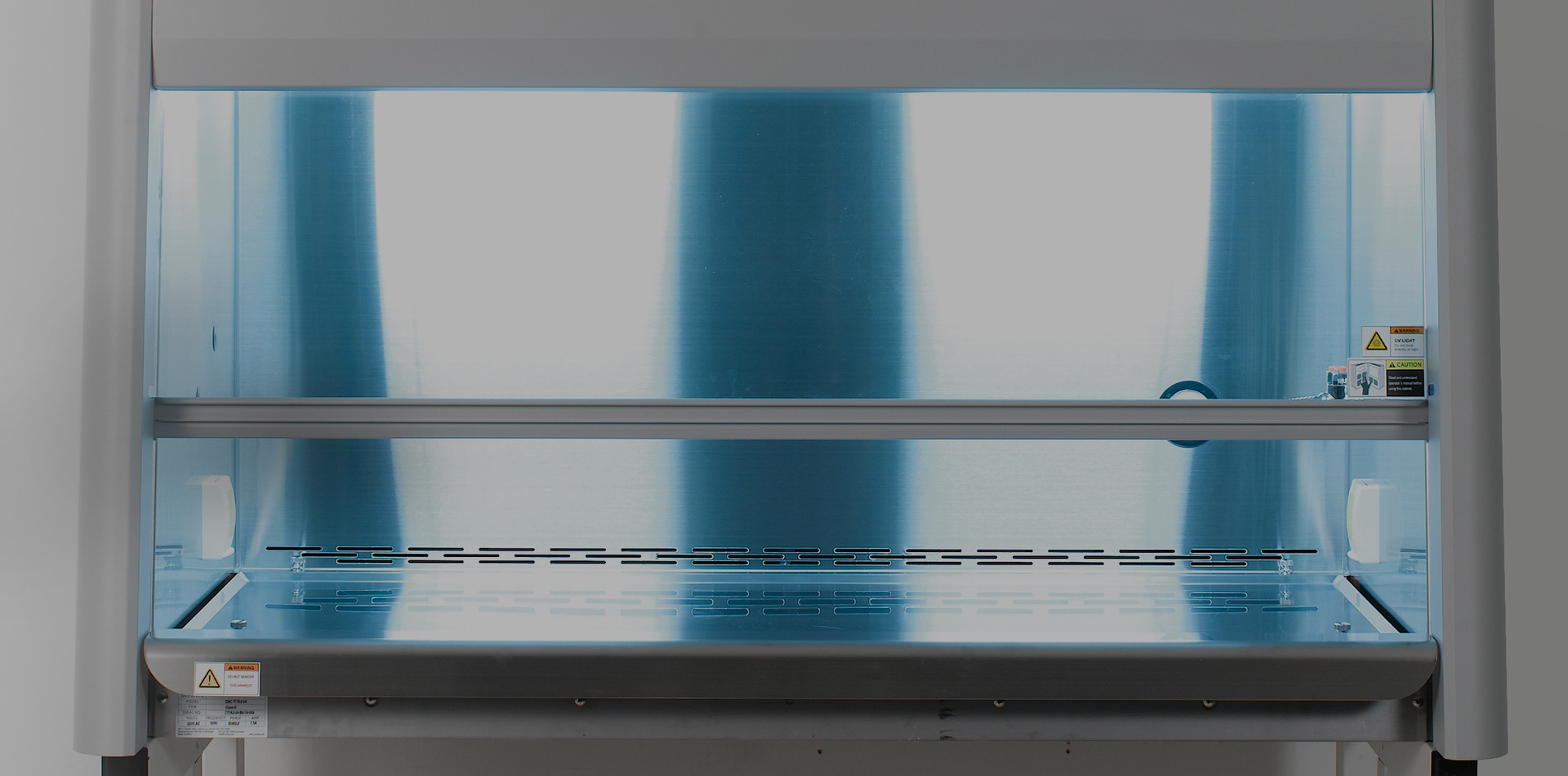

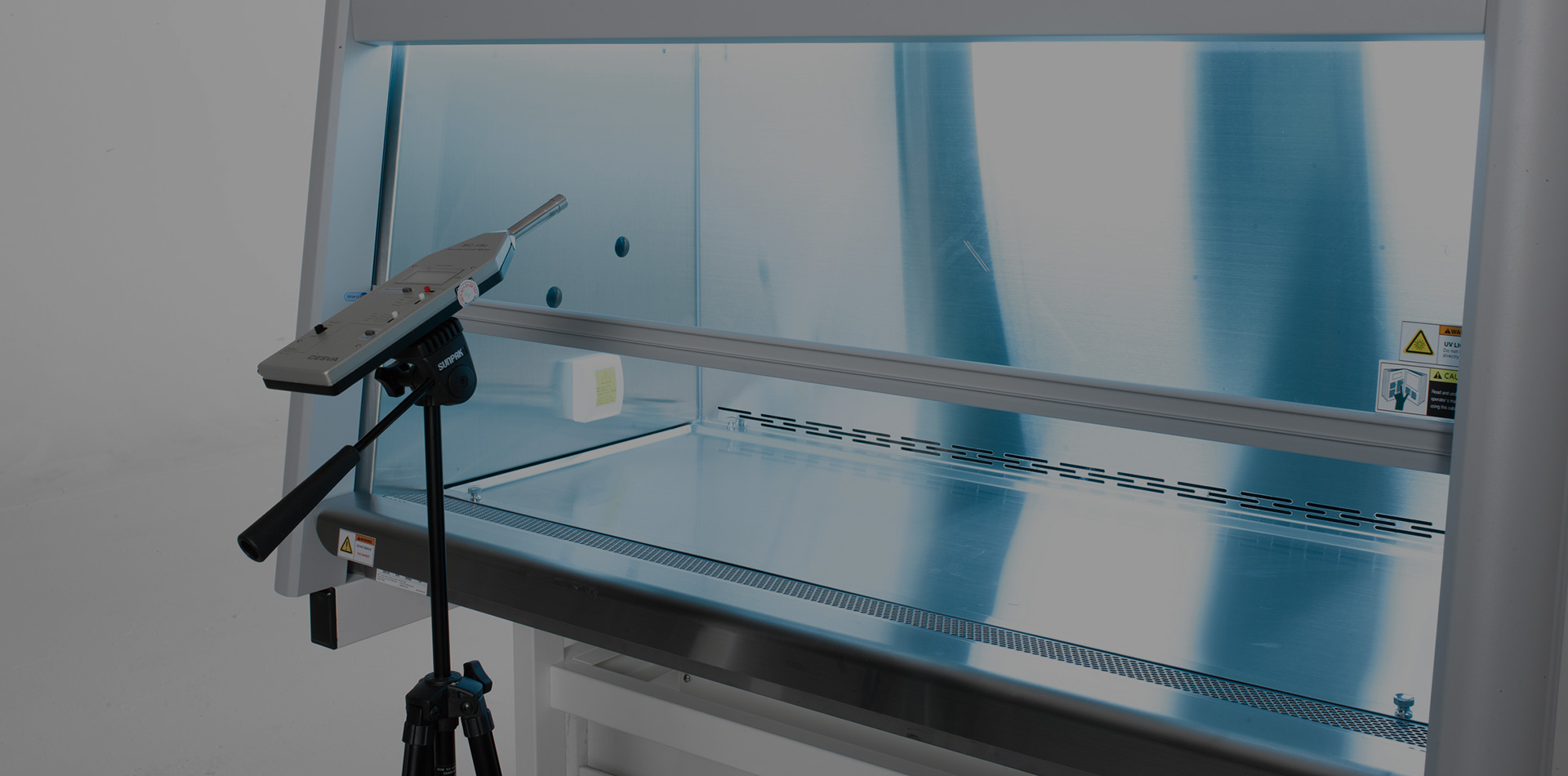

Validation service 01

Installation Qualification IQ

- IQ (Installation Qualification) is the process of checking and

verifying the facilities, systems, and equipment on the spot to

determine whether they are manufactured correctly according to the

design specifications and also to verify whether they are installed

properly to perform the desired functions by comparing them with

the requirement standard.

-

Validation service 02

Operational Competency Verification (OQ)

- Operation Qualification (OQ) process is done to

prove and document the ability of each systems and

related machinery to perform respective functions to

maintain the manufacturing process of the factory

-

Validation service 03

Performance Qualification (PQ)

- PQ (Performance Qualification) is a process

conducted on BSC equipment and its related

systems after they pass the OQ process to verify

and document the expected quality and

performance of the product.

Quality Control Test Items

-

Downflow

Velocity Test -

Intake Velocity

(Face Velocity) Test -

HEPA/ULPA

Filter Leak Test -

Airflow smoke

Patterns Test -

Site Installation

Assessment Test -

-

Personnel, Product,

Cross-Contamination

Protection -

Electrical

Test -

Noise/Vibration

Test -

Lighting Intensity

Test -

Particle Count

Test